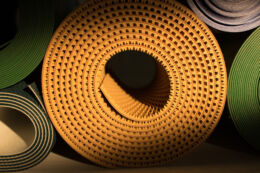

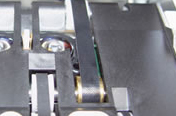

Positive Drive Belts

Hygiene and cross-contamination are the greatest challenges faced in the various food production and processing industries, which is why our range of Cleandrive positive drive belts are the top choice when it comes to fabricating conveyor belts for this industry sector.

Positive drive belts, also known as sprocket driven belts, reduce the risk of contamination that can occur due to product waste and residue collecting in gaps, hinges and dead spots. At the same time they offer the mechanical and chemical advantages of plastic modular belts.

The positive drive belts are easy and quick to clean, resistant to chemicals and bacterial growth and compliant with food-grade regulations.

With these belts you also get optimum functionality, with no risk of slippage, no need for tensioning devices and silent operation.

To find out more or to chat about configuring positive drive belts for your food-grade operation, call our knowledgeable sales team on 0117 954 1117, or fill in the contact form and we’ll get back to you.

Our conveyor belting engineers are highly experienced, well qualified and able to undertake fabrications and refurbishments for all sorts of conveyor operations. Provincial Rubber’s expert conveyor engineering services are offered to businesses large and small across South and South West England, South Wales, the Midlands and the central M4 corridor from our base in Bristol.

Provincial Rubber we offer a wide range of conveyor belting services including repairs, conveyor belt servicing, belt lagging, belt shortening and belt lengthening, belt clip jointing, conveyor belt repairs, custom fabrication, audits, site surveys, vulcanising, chute lining, engineering and conveyor belt lining services.

Other Conveyor & Transmission Belts categories

Extensive product selection

We pride ourselves on high-quality rubber products and maintain large stocks, so you don’t have to wait.Unparalleled product expertise

Our team of specialists offers extensive expertise to guide customers and find effective solutions to critical challenges.Outstanding customer support

We respond to inquiries promptly, ensure on-time delivery and work closely with customers to meet your unique needs.Some of the companies we supply products to: