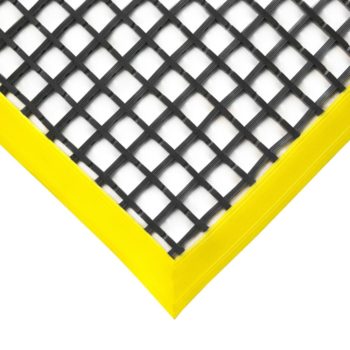

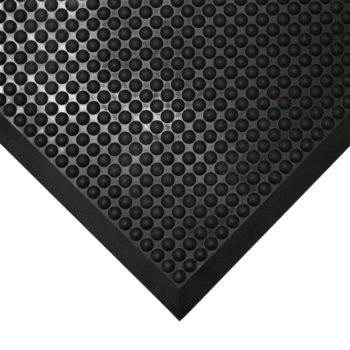

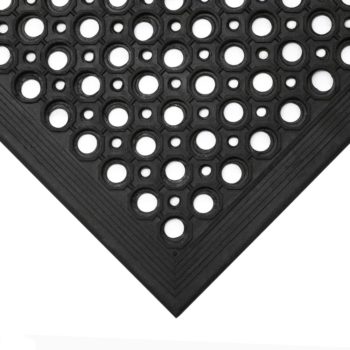

Our heavy-duty Fatigue Lift Solid Anti-Fatigue Interlocking Rubber Tiles can take a serious amount of punishment and continue to deliver excellent performance. With a fantastic fatigue-relief construction, these interlocking tiles are available in two versions. The standard version is manufactured from a nitrile and natural rubber blend. The second version is made from 100% nitrile. While both are durable and intended for use in challenging working environments, the 100% nitrile tiles are more resistant to oils, chemicals and grease, can cope with temperatures of up to 160℃, and even withstand molten glass spillages.

Uses and applications

Designed for industrial environments, the Fatigue Lift Matting is ideal for applications where employees are on their feet for extended periods, and the workplace demands a robust, reliable and hardwearing solution.

Fatigue Lift Solid Anti-Fatigue Interlocking Rubber Tiles technical specifications

Measuring 0.9 ㎡, the Fatigue Lift tiles are also available in corner and edge models with bevelled edging for improved safety and a more aesthetically pleasing look. The bevelled edge reduces trip hazards and is finished in either black or high-vis yellow. The matting conforms to Slip Resistance Test EN 13552 Category R10. The B1 version is tested to BS EN 13501-1:2002 Class Bfl-s1.

For more information on our Fatigue Lift Solid Anti-Fatigue Interlocking Rubber Tiles, contact our expert team at 0117 954 1117 or email info@provincialrubber.co.uk.

| Material | Standard – Natural rubber with 25% nitrile. Nitrile version – 100% nitrile |

|---|---|

| Surface Finish | Solid textured |

| Product Height | Standard – 18mm. Nitrile – 16mm |

| Operating Temperature | -20°C to +160°C |

| UV Resistance | Yes |

| Environmental Resistance | Suitable for wet and dry environments. Will withstand welding splatter and spillages of other hot materials |

| Installation Method | Loose lay interlocking tiles |

| Accessories | Bevelled edge / corners |

| Cleaning Method | Pressure hose with detergent if required |

| Product Performance | Conforms to Slip Resistance Test EN 13552 Category R10 |

| Flame Retardancy | B1 version tested to BS EN 13501-1:2002 Class Bfl-s1 |

| Country of Origin | Sri Lanka or India |

| Notes | Silicone is used in the production process of the mats and a residue will possibly be left on the mat |

Some of the companies we supply products to: